As a new generation of building decoration materials, integrated wallboard has many advantages such as fire prevention and moistureproof, sound insulation and heat insulation, environmental protection and beautiful appearance, etc., and splicing installation can effectively solve the disadvantages of traditional decoration process.

But different integrated wall materials have different advantages and disadvantages. Ah Yuan has sorted out the most comprehensive summary and published it today, hoping to help you.

Density board (MDF)

Density board also calls medium fiber board, it is to mix log into powder, after joining glue, high temperature is pressed and become.

Extremely poor waterproof performance, easy to expand after damp deformation. Density plate grip force should be the worst, long-term stress situation, easy to go out of position deformation.

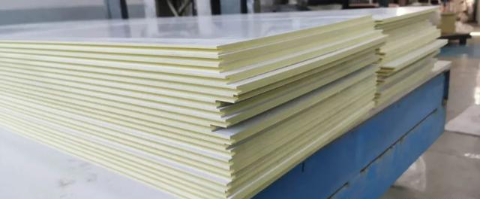

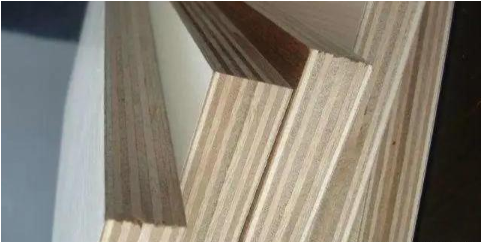

Multilaminate (plywood)

Multilayer board is composed of multilayer 1mm± thin plates, joined with glue and pressed, so it is also called plywood.

This kind of plate holds nail force very strong, stability is good, but waterproof and environmental protection sex does not reach the requirement.

Solid wood

Solid wood is cut from whole wood and made from whole wood (log).

Strong and durable, grain is natural, hygroscopic sex and permeability are better, but as a result of real board construction craft requirement is very tall, and the price is more expensive, what use in daily decoration is not much instead.

Uv board

UV plate more PVC recycling materials and calcium powder, and the content of calcium powder is relatively high.

Environmental protection performance is higher than multilayer board and density board, but as a result of the environmental protection of recovery material cannot determine, and surface film is used more low-end oily film, not good decoration effect.

Bamboo and wood fibreboard

Bamboo and wood fibreboard production raw materials are mainly recycled PVC materials and calcium powder, due to numerous manufacturers, environmental performance is not easy to distinguish.

Its surface treatment is also mostly laminating, laminating material is mostly oily film, environmental protection is poor, laminating process is not environmentally friendly gellan laminating, resulting in the finished product containing formaldehyde and other toxic substances.

PVC plate

In recent years, PVC large board appears in the market more high-end environmental protection products, with the characteristics of large size and flexible customization, but the substrate surface coating process is uneven, at present, many manufacturers use not environmentally friendly gellan, with a pungent smell.

Compared from the quality, each PVC large board manufacturers also have a large gap, some poor quality plate surface hardness is low easily damaged.

ASA plate